As high-tech fields demand smaller, more intricate parts, Wire Electrical Discharge Machining, or Wire EDM, has become a key tool in micro-manufacturing. Because it cuts without touching the workpiece, Wire EDM delivers tolerances that traditional mills and lathes often miss-a feature that aerospace, medical-device, chip-making, and micro-robotics shops now count on.

For CNC precision machining suppliers trying to meet today’s tough B2B specs, Wire EDM combines pinpoint accuracy, wide material choice, and nearly limitless design freedom. In the paragraphs that follow, we explain how Wire EDM is reshaping the production of tiny, complex components and why any future-ready supply chain needs a wire machine on the floor.

Understanding Wire EDM in Precision Manufacturing

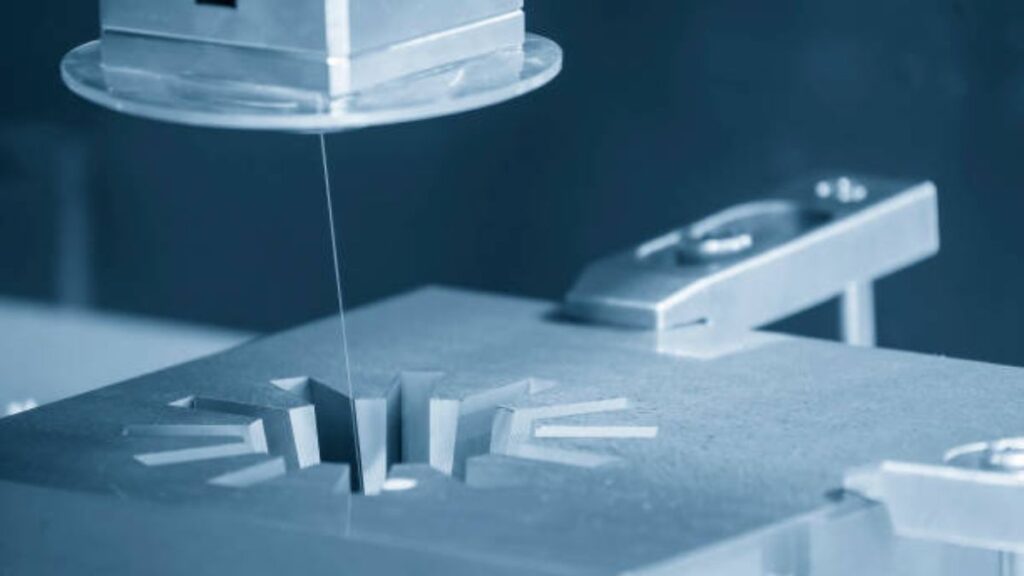

Wire EDM is a subtractive method that feeds a thin, electrically live wire through a workpiece to slice metal with remarkable exactness. Because sparks, not cutting edges, erode the material and there is no direct contact, deflection, stress, or heat build-up remain minimal. That immunity to distortion makes wire cutting ideal for delicate jobs that would warp or crumble under conventional tooling.

Wire EDM cuts metal with such fine detail that it routinely holds tolerances of ±1 micron and leaves a mirror-smooth finish. For CNC precision machining suppliers, that accuracy allows them to manufacture key micro-parts for demanding markets, such as:

- Medical implants and surgical tools

- Aerospace turbine and fuel-injection components

- Micro-electromechanical systems (MEMS)

- High-performance connectors and electrical contacts

- Miniaturized robots, sensors, and actuators

Because the machine works on material that is already hardened, it produces prototypes, small runs, and top-tier tooling with almost no warping or added strain.

The Unique Advantages of Wire EDM for B2B Manufacturing

Wire EDM shines whenever a part needs internal shapes, razor-sharp corners, and tight dimensions, yet comes off the table burr-free and ready to use.

For B2B firms that depend on suppliers for repeatable quality and accuracy, the process offers clear advantages:

- High Precision: The method often surpasses what standard CNC milling or turning can deliver.

- No Mechanical Stress: Since the cutting wire never touches the workpiece, even brittle items stay straight, smooth, and unchanged in size.

- Superior Surface Finish: Wire EDM can leave surfaces as smooth as Ra 0.1 µm, so polishing is often cut or completely dropped.

- Material Flexibility: The process works on superalloys, titanium, tungsten, Inconel, and even hardened tool steels with ease.

- Reduced Tooling Costs: Shops save money because there is little need for pricey cutting tools or constant tool swaps.

In a world where speed and quality set brands apart, Wire EDM lets CNC precision machining suppliers ship parts that clear ISO, AS9100, and other tough standards. That speed-to-market edge can win contracts and keep customers coming back.

Why Wire EDM Matters in Micro-Manufacturing

Micro-manufacturing makes parts smaller than 1 mm in at least two directions. Think pacemakers, micro-drones, or gear inside chip fabs-every bit has to work or lives and profits hang in the balance. Tolerances are razor-thin, shapes are curvy and twisted, and even a tiny error can ground an entire project.

Wire EDM shines here. It cuts micro-slots, paper-thin walls, and sharp radii that rotary cutters simply can not touch without breaking, and it does so while keeping heat and mess to a minimum. That thermal control and clean operation matter in hospitals and fabs alike, because dust, chips, or unexpected expansion could ruin a batch before anyone notices.

As products shrink, engineers need suppliers skilled in wire EDM and micro-machining, not just big machines but real know-how. This is more than a passing fad; it is reshaping how things are designed and made every day.

Key Applications Where Wire EDM Excels

Wire EDM cuts metal with such accuracy that whole industries lean on it whenever parts must fit perfectly. Here are a few areas where that precision really matters:

Aerospace and Defense

In aerospace, it makes turbine blades, brackets, and other parts from tough alloys like titanium or Inconel. Because the process generates little heat, the metal stays stable and the finished piece can survive extreme flight conditions.

Medical Device Manufacturing

Surgical implants or tiny stents need to be smooth and exact. Wire EDM leaves edges that are clean, biocompatible, and up to FDA and ISO 13485 rules.

Semiconductor and Microelectronics

One tiny misalignment in chip carriers or packaging can crash a whole system. Wire EDM cuts mold cavities and heat sinks with tolerances measured in microns, keeping electronic gear reliable.

Robotics and Automation

In tight robot shells, gears, housings, and special motion parts need near-impossible accuracy, and only Wire EDM delivers it. As machines shrink, the call for micro-parts rises sharply.

Selecting the Right CNC Precision Machining Supplier for Wire EDM

Wire EDM is pricey to run and tough to master, so not every job shop can meet micro-manufacturings high bar. B2B buyers should screen CNC precision machining suppliers against these points:

- Technical Capabilities: Do they run multi-axis Wire EDM that holds measurements in microns?

- Experience: Can they show a portfolio from tough fields like aerospace, medical, or robotics?

- Quality Assurance: What in-process gauges and final tools prove every part meets the print?

- Material Expertise: Will they cut stubborn alloys, hardened steel, or custom metals without tearing tools?

- Turnaround and Scalability: Can they shift from prototype to thousands of units and keep quality steady?

Vendors who know Wire EDM inside and out become more than suppliers; they turn into partners who add value with every design tweak.

Future Trends in Wire EDM and Micro-Manufacturing

Wire EDMs are entering a new era because shop floors are getting smarter. With Industry 4.0 tools like IoT sensors, AI quality checks, and cloud dashboards spreading fast, these machines will link up, sharing real-time data that boosts accuracy and triggers maintenance before a breakdown.

Watch for these game-changing features:

- Automated Wire-Changing: Keeps the cut going and cuts out wasted setup time.

- High-Speed EDM Wire: Zips through material quickly while still leaving a clean edge.

- Micron-Level Monitoring: Tracks every pass so parts stay identical from start to finish.

- Digital-Twin Links: Builds a virtual copy of each job for test runs and process tweaks.

These upgrades let CNC precision machining suppliers ramp up output without losing the tight tolerances of small parts demand.

Conclusion: Precision Without Compromise

Wire EDM has become a cornerstone of modern micro-manufacturing. As makers shrink shapes and pile on features, rock-solid accuracy is what keeps new ideas moving. Shops that double down on Wire EDM will not just keep pace; they will lead the next wave of smart production.

Whether you’re making a new heart stent or a high-tech jet sensor, Wire EDM gives you the peace of mind that every part comes out precise, uniform, and without shortcuts.