In the fast-paced world of food and pharmaceutical production, consistency and quality are paramount. Manufacturers depend on specialized equipment to mix ingredients efficiently and ensure every batch meets rigorous standards. The ribbon mixer stands out as a core solution, combining thoughtful engineering for both small-batch specialty operations and high-volume production environments.

These versatile machines streamline the blending process, reducing labor and improving productivity while meeting tough hygiene requirements. As consumer demand and regulatory expectations continue to rise, ribbon blenders help manufacturers achieve reliable results, supporting safe and appealing products from snacks to lifesaving medications.

Design and Functionality

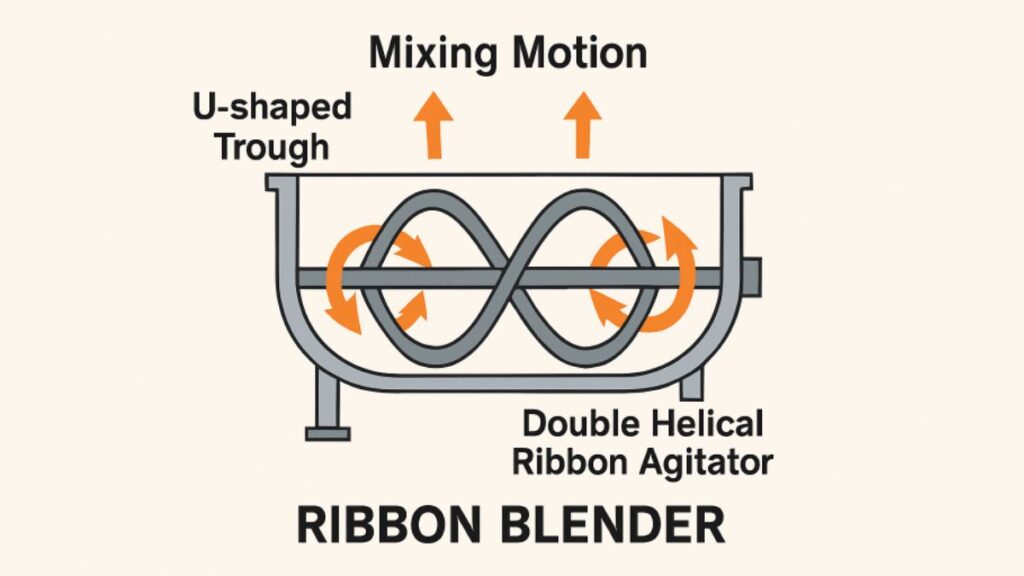

The heart of a ribbon blender lies in its simple yet highly effective mechanical structure. It consists of a horizontally oriented, U-shaped trough fitted with a double helical ribbon agitator. As the blender operates, the ribbon agitator moves ingredients both radially and laterally. The outer ribbon pushes materials in one direction along the length of the trough, while the inner ribbon simultaneously moves them in the opposite direction. This dual movement produces a consistent, rapid blending action, ensuring a uniform mix regardless of batch size.

This design helps minimize dead spots and prevents localized clumping or separation of materials. Variations are available to accommodate a range of material properties, from free-flowing powders to cohesive compounds. Innovations in ribbon configuration, rotational speed, and trough geometries further allow processors to tailor mixing for specific needs.

Because the ribbon blender’s internal surfaces are easy to access and clean, it helps manufacturers maintain product integrity and reduce the risk of cross-contamination between production runs. This design feature is especially critical in industries where allergen control or batch-to-batch purity is strictly required.

Applications in the Food Industry

In the food sector, ribbon blenders are trusted for a wide range of dry-mixing tasks. They are typically used for products such as flour blends, dry baking mixes, spice combinations, protein powders, and snack seasonings. The gentle yet thorough mixing action is ideal for preserving the structure of sensitive ingredients, such as dehydrated fruits or inclusions like nuts or chocolate chips, maintaining the final product’s desired texture and uniformity.

Additionally, ribbon blenders support flavor development and ensure even distribution of functional additives, such as vitamins, minerals, and preservatives, throughout a batch. Automation and precise recipe control also reduce human error, further enhancing product safety and reliability.

Applications in the Pharmaceutical Industry

Pharmaceutical production is defined by its stringent requirements for uniformity and cleanliness. Ribbon blenders are widely used to mix powders and granules for tablets, capsules, and other dosage forms, ensuring that each unit contains the correct proportions of active and inactive ingredients. This level of precision is critical to patient safety and regulatory compliance.

Many pharmaceutical ribbon blenders are designed with enhanced material containment features, air-handling systems, and seamless, polished surfaces to prevent powder accumulation and simplify cleaning. The ability to custom-engineer blenders for specific pharmaceutical processes makes them an asset for both generic and specialty drug manufacturers.

Advancements in Ribbon Blender Technology

The continued evolution of ribbon blender technology responds to the growing need for higher output and consistent performance. For example, Intelligent Blends has expanded its capabilities by introducing a high-capacity ribbon blender, increasing production capacity to over 10 million pounds annually. This investment not only supports large-scale manufacturing but also supports product consistency in beverage blends and other applications.

Today’s ribbon blenders may include programmable controls, automated batch management, and real-time monitoring for enhanced production oversight. Improvements in ribbon design, energy efficiency, and discharge options also enable companies to achieve new levels of performance and operational flexibility.

Hygiene and Safety Standards

Both food and pharmaceutical facilities must meet strict hygiene and safety benchmarks. Ribbon blenders rise to the challenge with features such as seamless welds, polished stainless steel construction, and easy-open inspection and cleaning access doors. These design attributes help eliminate harborage points for bacteria and ensure rapid batch changeovers, two critical factors for regulatory compliance.

Companies like Ross have introduced innovations, such as PFA-coated ribbon blenders, to enhance containment and hygiene in applications that are especially sensitive. Such adaptations ensure that allergen and contaminant risks are minimized, safeguarding public health and maintaining regulatory standing.

Choosing the Right Ribbon Blender

The process of selecting a ribbon blender should begin with an accurate assessment of production needs. Key considerations include the frequency and batch size of mixing cycles, properties of the materials being blended, and specific cleaning and changeover requirements. In highly regulated industries, it is also important to ensure that all equipment meets or exceeds the relevant safety, hygiene, and documentation standards.

Consulting with reputable manufacturers can help specify the right agitator designs, construction materials, and control options tailored to unique manufacturing challenges. The right ribbon blender becomes a strategic investment in both product quality and operational efficiency.

Conclusion

Ribbon blenders have become indispensable in food and pharmaceutical manufacturing. With their proven ability to deliver fast, thorough, and reproducible mixing results, they help companies uphold the highest standards for quality, safety, and efficiency. Continued innovations ensure ribbon blenders remain at the forefront of processing technology, supporting the industry’s ongoing evolution and its commitment to producing safe, high-quality products.