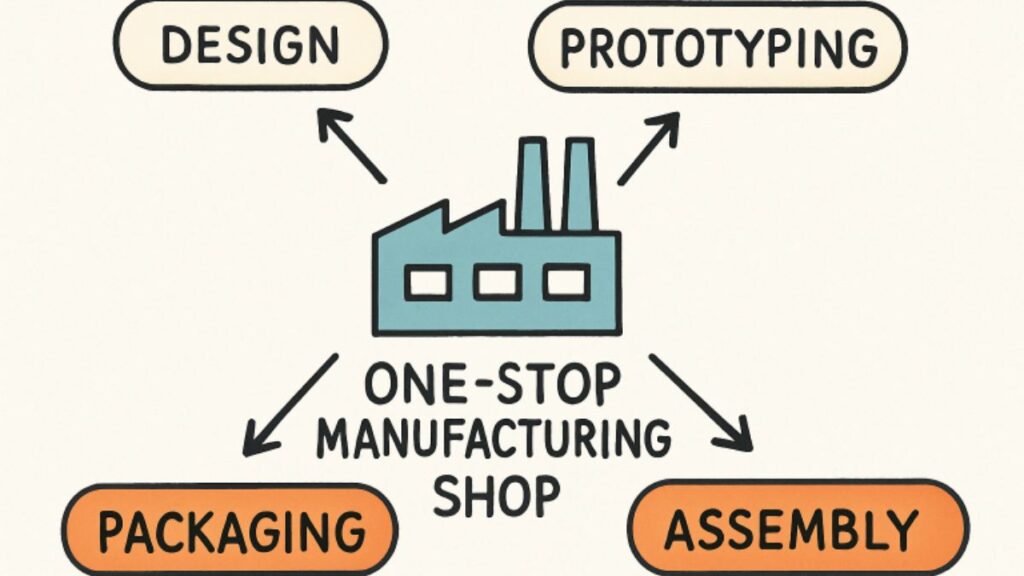

Staying ahead in today’s rapidly evolving business environment requires innovative strategies to optimize resources and ensure high-quality production. Companies often turn to specialized partners, such as a design engineering company, to achieve these operational goals. By engaging with a one-stop contract manufacturing shop, businesses can sidestep the complications of juggling multiple vendors and instead benefit from a seamless, integrated solution.

Choosing a single partner for the entire manufacturing process radically streamlines supply chain logistics. This approach is not only cost-effective but also enhances consistency, minimizes quality issues, and accelerates the time to market. As global competition intensifies, organizations that partner with comprehensive manufacturing solutions position themselves for greater success by focusing resources on core competencies while leveraging advanced manufacturing expertise.

The transition to a one-stop shop model is increasingly appealing to both small startups and established enterprises. Consolidated manufacturing operations offer the flexibility needed to adapt to market fluctuations and technological advancements. This end-to-end management reduces potential risks and sets the foundation for better quality control and innovation.

Moreover, this approach frees internal teams from the burden of coordinating numerous suppliers, enabling them to focus their energy on strategic activities that drive business growth.

Cost Savings and Efficiency

Cost containment remains a top priority for growing businesses. By consolidating design, prototyping, sourcing, production, and packaging within a single contract manufacturing shop, companies can benefit from significant administrative savings. Eliminating the need for multiple purchase orders and supplier negotiations reduces overhead and minimizes logistical complexities. As outlined by Harvard Business Review, simplification of the supply chain is a proven way to mitigate avoidable expenses.

This streamlined approach also reduces the risk of miscommunication and costly production delays. Centralized workflows afford greater transparency and coordination, driving operational efficiency from project kickoff to final delivery.

Enhanced Quality Control

Delivering superior products relies on rigorous quality standards at every stage of manufacturing. A one-stop contract manufacturer manages your project from start to finish, ensuring uniformity and adherence to quality benchmarks—such as ISO 9001:2015 or industry-specific certifications. With integrated oversight, potential defects or inconsistencies are identified and corrected early in the process, lowering the risk of downstream issues and costly recalls.

Maintaining Traceability

Centralized systems also make it easier to track the journey of each component, supporting traceability, which is vital for regulated industries such as the medical device and automotive sectors. This holistic quality management not only protects your brand but also builds customer trust over time.

Faster Time-to-Market

Speed is critical in competitive markets where product innovation cycles are shortening continually. One-stop shops coordinate design, development, prototyping, and production in a seamless flow, eliminating the wait times associated with inter-supplier transitions. This agility enables businesses to bring new products to market faster and capitalize on emerging trends. Companies that master rapid new product introductions often outperform their competitors and strengthen their market presence, as discussed in Forbes.

Scalability and Flexibility

Fluctuations in market demand are inevitable, but one-stop contract manufacturers offer the scalability to meet changing needs. Whether launching a new product, responding to seasonal demands, or expanding globally, these manufacturers are equipped to ramp up or scale down production volumes with ease. This agility is especially valuable for startups that need small initial runs and established enterprises that require global capacity.

Simplified Communication

Working with multiple vendors often leads to misunderstandings, misaligned priorities, and slow project updates. A one-stop manufacturing partner centralizes all communication, giving clients a single point of contact who manages timelines, addresses concerns, and aligns resources across every project phase. This clarity reduces the risk of missed expectations, streamlines change requests, and ensures that every stakeholder receives timely information.

Access to Advanced Technologies

Modern manufacturing technologies, ranging from robotic assembly to high-speed CNC machining and digital quality tracking systems, require substantial capital investment. One-stop contract manufacturers frequently update their equipment and software, granting clients access to cutting-edge capabilities without the high upfront costs. This access can drive greater product innovation, improve competitive differentiation, and enhance customer performance in demanding markets.

Risk Mitigation

Reliance on multiple suppliers introduces vulnerabilities: extended lead times, mismatched material specifications, and quality inconsistencies. When a single entity manages all stages of the supply chain, businesses benefit from enhanced supply chain stability and robust risk management. Issues are quickly identified and addressed without the finger-pointing that can arise when multiple suppliers are involved. In uncertain times, this reliability is invaluable for maintaining business continuity.

Conclusion

Choosing a one-stop contract manufacturing shop offers an integrated, end-to-end approach that results in cost savings, superior quality, accelerated time-to-market, and greater flexibility in response to dynamic market conditions. With simpler communication and better access to advanced technologies, businesses reduce risk and strengthen their market position. Consolidating manufacturing with a trusted partner allows organizations to focus more on growth and less on supply chain complexities, building a foundation for lasting success.